CNC Prototyping With LK Mould in China

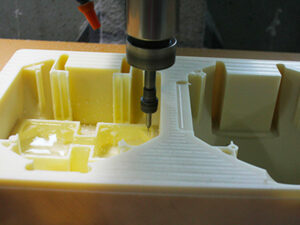

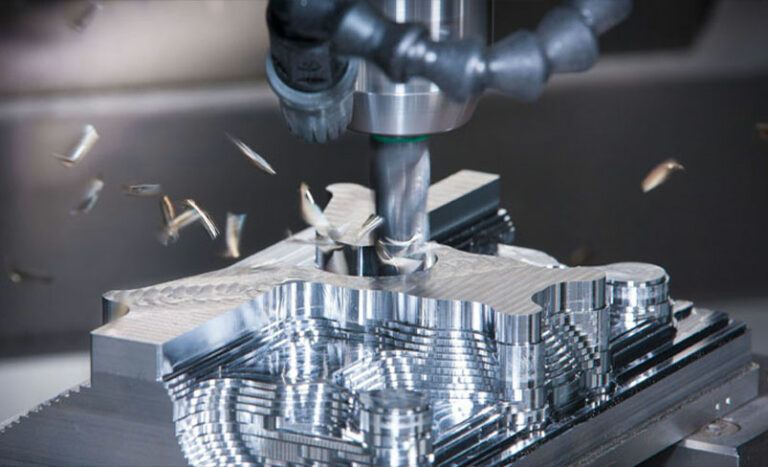

5-Axis CNC-PROTOTYPING

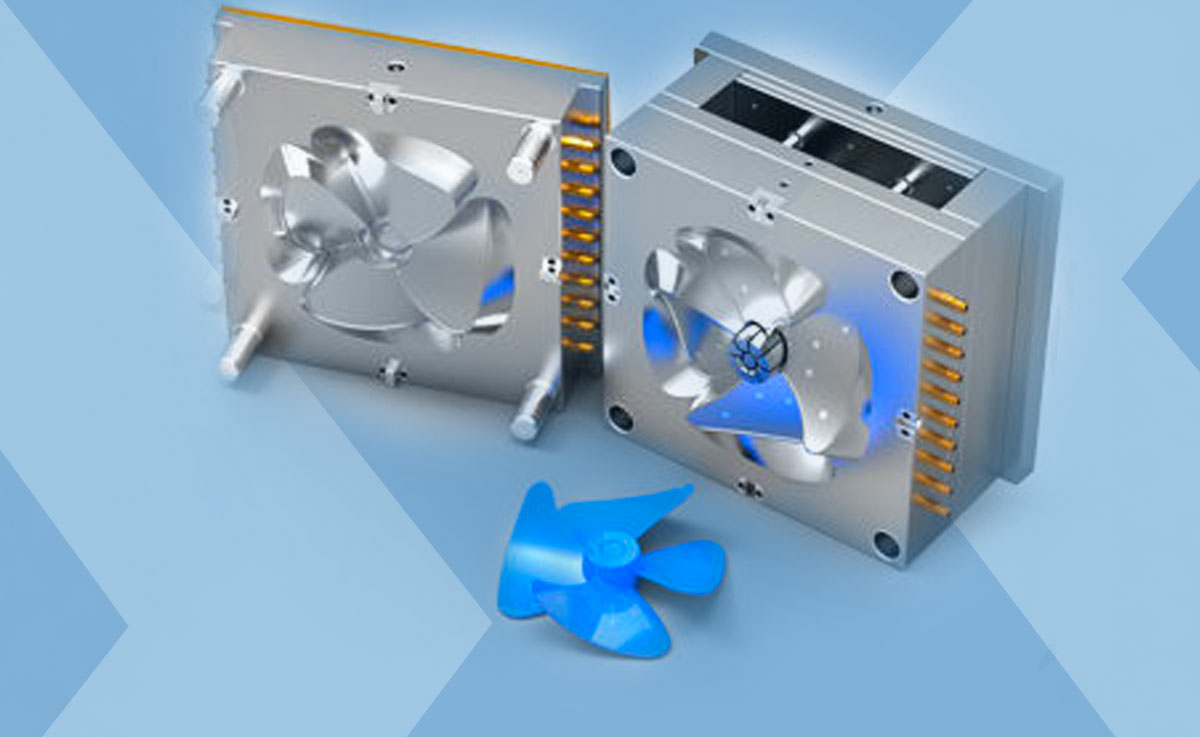

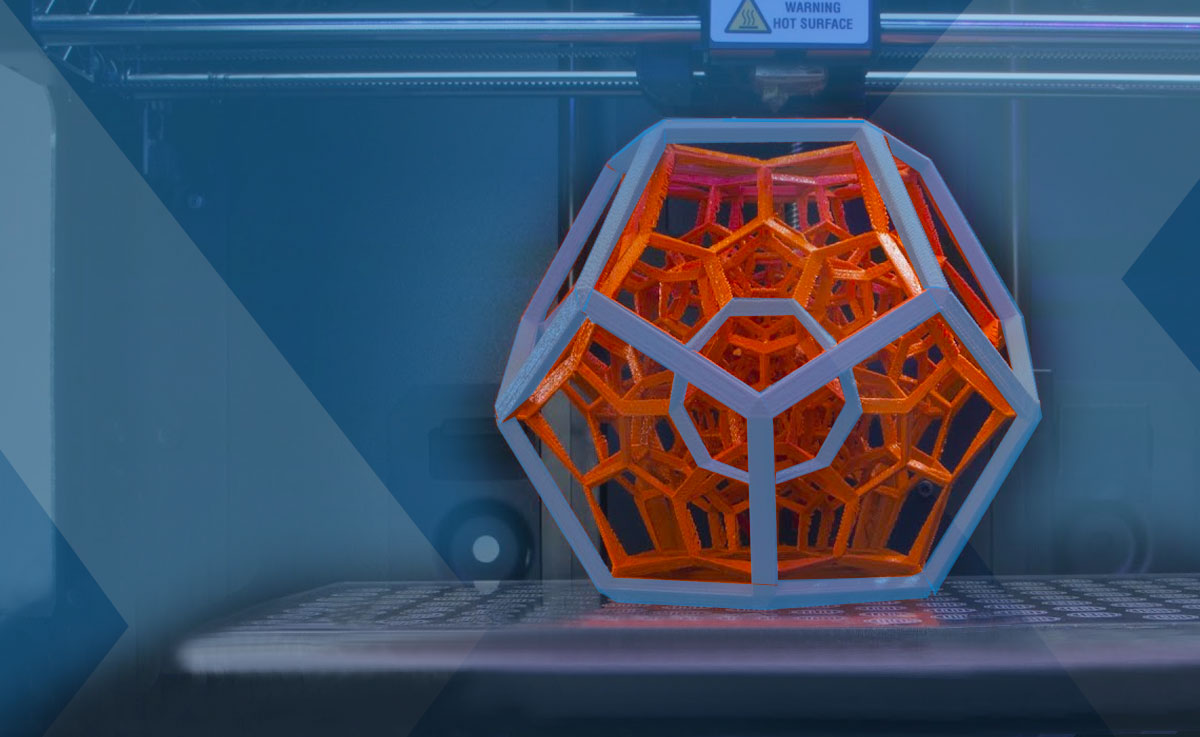

As a specialist in prototypes and small series, LK Mould China produces high-quality CNC-turned and milled parts according to your drawings. LK-Mould manufactures CNC Machining and CNC pre-series in China on CNC-controlled universal milling machines. We cut all common plastics and metals such as brass, steel, aluminum, ABS, PP, PVC, PA6, PA66, PA12, PBT, POM or PC.

CNC Machining Services

- Design, Prototypes, Serial Production

- Industry-leading turnaround times

- Efficiency & High Quality

- 22+ Years Skilled Experience

CNC-PROTOTYPES MATERIALS

LK-Mould Ltd. manufactures your high-precision CNC components on modern turning and milling machines. Our product portfolio ranges from Prototype Construction to Serial Production.

Applications:

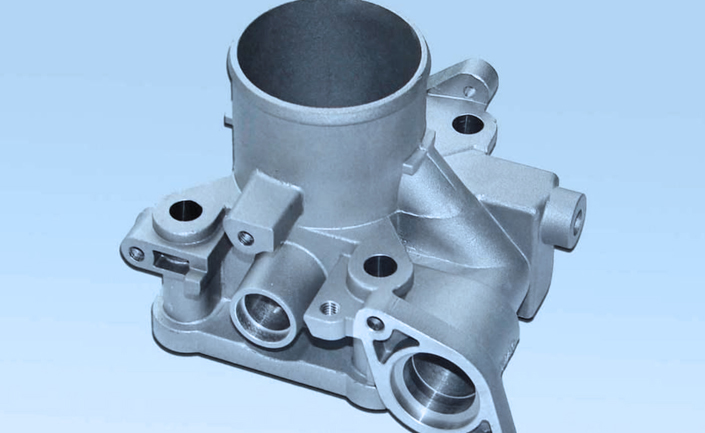

– Automotive Industry

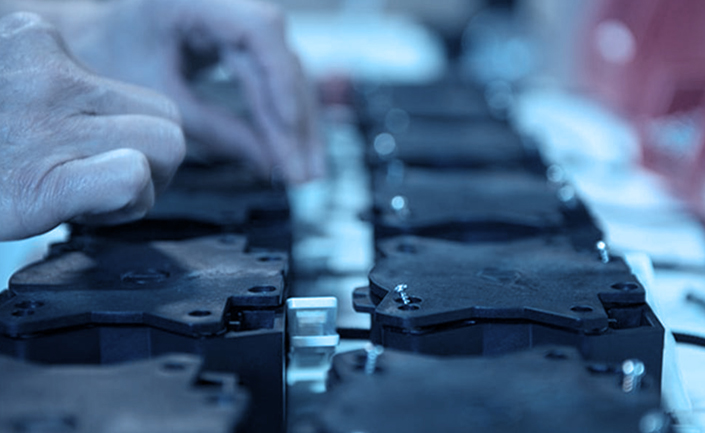

– Electrical industry

– Device Industry

– Machinery Industry

– Home application industry

CNC Prototyping, CNC model making, CNC small series – LK-Mould is your partner.

We are using the following materials to turn/mill your CNC prototypes:

Steel, Aluminum, POM (Acetal), PMMA (Acryl), ABS, Polycarbonate, Acetal, HDPE, LDPE, Nylon 66, PEEK, PEI (Ultem), PTFE, UHMW, Brass, Copper, mild steel, Magnesium, Foam and many more.

Request a no-obligation quotation for your plastic or aluminum CNC-Prototypes!

PROTOTYPES AND SERIES

We manufacture complex turned and milled parts as prototypes and serial products, with a batch size of up to 10,000 pieces.

Our Robust Capabilities

PRODUCTION SIZE

Our production capacity is individual to your request and ranges from 1 to 10,000 pieces per order. Please ask for details.

QUALITY

LK Mould is well known for its high-quality production output. We are also certified after norm ISO 9001:2018 and TS16494.

LK-MOULD CHINA

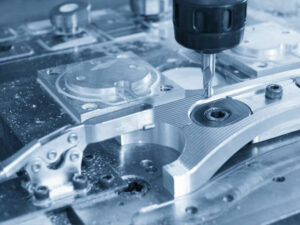

CNC MACHINES

Our high-speed CNC machining operation allows us to facilitate short lead times and competitive pricing on precision CNC rapid prototypes and masters, and also for short-run needs, hybrid molds, and presentation models. We operate the latest software and machines manufactured by Fadal and HAAS, including part beds up to 84 x 30, which are equipped with 4th-axis motion. LK Mould can hold all tolerances to within +/- 0.2 mm to 0.3 mm.

Complex feature and contoured surface programming is handled with the latest version of Mastercam, a package that programs quickly and runs NC check to verify each setup and cutter path is accurate.

We manufacture high-quality CNC-milled parts in China as well as CNC-turned parts in China according to your drawings in prototype size and small series. Benefit from our experience in the production of cost-effective CNC-machined models, prototypes, samples and small series.

| BRAND | MODELL | SIZE (MM) | QUANTITY |

|---|---|---|---|

| CNC Machine Center | YCM-FV 1060A YCM-FV 65A HSCH-500I Makino S33 | 1060x520x540 650x480x540 500x400x200 650x500x450 | 1 1 3 4 |

| EDM Machine | TURBO-500CNC YAKE 650 YAKE 540 YAKE 450 YAKE 430 MITSUBISHI EA12DM | 500x500x400 650x500x450 540x440x200 450x350x200 400x300x200 400x300x300 | 1 2 3 4 1 |

| Grinding Machine | HYFAIRHF-618S | 450x160x150 | 4 |

| Drilling Machine | H5-32 | Dim45x1000 | 3 |

| Lathe Machine | C 6232A 1 | Dim320x1000 | 2 |

The LK Mould team is here to answer your questions

Need Consultation for your Project?

Inquiry and Project Specifications

The customer sends us project specifications and requirements. This typically includes design files, material preferences, quantities, and any specific tolerances or quality standards.

Design and Engineering Review

Our design and engineering team evaluates the project's feasibility and requirements. By working closely with you we will refine the design for manufacturability, cost-effectiveness, and functionality.

Manufacturing and Quality Assurance

Once the design is finalized and approved, the manufacturing process begins. Stringent quality control measures are applied to ensure that each component meets the specified standards.

Assembly and Delivery

The final step involves the assembling of individual components into the final product. After assembly and a final quality check, the products are carefully packaged and delivered to your specified location.

LK MOULD Services

Read more about our services by clicking on the topics below: