QUALITY & Certifications

LK Mould Quality Management

For more than 22 years, LK MOULD has been producing plastic injection molds in China for plastic parts, used for automotive and household appliances, of the highest standard. We offer our customers solutions from one single source, and have an experienced and professional team, from design to manufacturing to customer service.

In order to meet the requirements of our customers, we carefully examine the materials, components, and products used. Together with renowned testing institutes, we ensure that the requirements are met. For this reason, we can proudly prove our certificates.

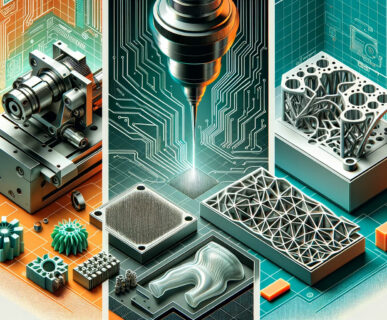

We produce individual plastic products at the highest level and with a variety of processes on over 10,000 sqm. workspaces, such as rapid prototyping, 3D printing, or plastic injection molding.

- All In One Factory Partner

- Knowledgeable Expert Team

- High Quality Solutions

- 24/7 Quick Supports

Sqm Workspace

Molds/Year

SKILLED EXPERTS

QUALITY MANAGEMENT

LK Mould QM Certificates

ISO 9001

LK Mould is certified according to ISO 9001: 2008 including semi-finished products and production of precision plastic molds.

- Quality Assurance

- State-of-the-art Machines

- Skilled Team Members

- Best Report Services

ISO/TS16949

LK Mould is certified according to ISO/TS16494 which includes Auto parts, mold design, production, and service procedures. Our quality system meets the requirements of TS16494.

- Product Quality Planning

- Effects Analysis

- Calibrated instruments

- Best Quality Services

ISO 14001

LK Mould is certified according to ISO 14001: 2015, including environmental management activities of auto parts, electronic products, molds.

- Control Plan

- Process Flowcharts Services

- In Process Visual Inspection

- Final Audit Quality

Your Factory in China for Injection Molding

We are your expert in the following areas: Rapid Tooling & Rapid Manufacturing, Injection Molding Construction & Production, Plastic Injection Molding China, Part Production by Injection Molding, Plastic components & plastic parts from China, 3D printing China and Aluminum serial parts, CNC-Prototyping and CNC-machining, Metal parts and hardware stamping Parts, Customized Diecasting Aluminum and Zinc productsHow to, Case Studies, Materials, and More

LK MOULD - TECH BLOG

Mastering Die Casting – How to Manufacture Successfully in

China's Die-Casting production has skyrocketed in the past. With its

Read Deatils

Understanding Injection Molding Cost – A Complete Guide

In the world of manufacturing, injection molding is a widely

Read Deatils

Mastering The Best Surfaces for CNC Machined Parts

Mastering Aesthetics and Functionality: The Best Surfaces for CNC Machined

Read Deatils

Exploring Cost-Effective Alternatives to Injection Molding for Low Volume

Efficient Manufacturing on a Budget: Cost-Effective Alternatives to Injection Molding

Read Deatils