Top 6 Advantages of Using CNC Machining for Rapid Prototyping

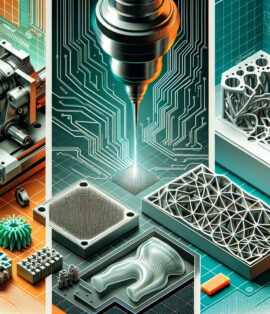

Rapid prototyping is a critical phase in the product development process, offering designers and engineers the ability to iterate quickly and efficiently. Among the various technologies available, CNC machining stands as a beacon of precision, speed, and versatility. In this article, we explore the top six advantages of using CNC machining for rapid prototyping, elucidating why this technique remains a staple in manufacturing toolboxes worldwide.

1. Unmatched Precision and Accuracy

CNC machining is synonymous with precision. The ability to execute complex cuts and intricate details with exactness is paramount, especially when it comes to prototyping components that must meet stringent specifications. CNC machines operate under strict tolerances, and their computerized nature means that human error is significantly reduced. This level of accuracy ensures that prototypes are a near-perfect representation of the final product, allowing for effective testing and validation.

2. High-Speed Production

Time is of the essence in product development. CNC machining accelerates the prototyping process, as it can produce parts rapidly without compromising quality. Unlike additive manufacturing methods that build layer by layer, CNC machines can swiftly remove material to shape the part, which can lead to quicker turnarounds. This speed is beneficial for getting products to market faster, enabling companies to stay ahead in competitive industries.

3. Material Versatility

One of the standout features of CNC machining is its compatibility with a wide range of materials. From plastics to metals, the technology can handle various substrates, providing flexibility in prototype development. This versatility allows for material properties that are closer to the final production materials, thus enabling more accurate performance testing and material-specific evaluations.

4. Seamless Integration with CAD/CAM

CNC machining’s harmonious relationship with CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) software streamlines the prototyping process. From a digital blueprint to a physical part, the transition is seamless. The software provides a direct path to the CNC machine, which then executes the design with precision. This integration not only saves time but also allows for straightforward revisions. Design changes can be quickly implemented, ensuring that the prototype evolves as needed with minimal downtime.

5. Cost-Effective for Low Volume Production

While prototyping often involves the production of a single unit, CNC machining stands out when multiple prototypes or low-volume batches are required. Unlike other manufacturing processes that require costly molds or setups, CNC machines can switch between production runs with minimal setup changes. This capability makes it a cost-effective solution for producing small quantities, allowing designers to test multiple variations of a prototype without incurring significant additional costs.

6. Superior Surface Finish and Detail

CNC machining doesn’t just excel in the realms of speed and efficiency; it also delivers superior surface finishes that often require little to no post-processing. The quality of the surface finish is crucial for functional testing and aesthetic evaluation of prototypes. CNC machining can produce parts with fine details and smooth surfaces right off the machine, which is particularly beneficial for prototypes that will be used in consumer testing or as master models for casting processes.

Conclusion

In conclusion, CNC machining is a formidable tool in the arsenal of rapid prototyping technologies. Its unmatched precision, high-speed production, material versatility, seamless integration with CAD/CAM software, cost-effectiveness for low-volume production, and superior surface finish and detail make it an indispensable method for bringing ideas to life swiftly and effectively.

As the industry continues to evolve, CNC machining remains at the forefront, continually adapting and integrating with new technological advancements. For those seeking to refine their prototyping processes and enhance their product development, embracing the advantages of CNC machining is not just a choice, but a strategic imperative.

For an in-depth exploration of how our CNC machining services can elevate your prototyping phase, visit our CNC Machining service page. And for broader insights into the world of rapid prototyping, don’t miss out on the wealth of information available on our Rapid Prototyping service page.

Our team is here to answer your questions

Let’s talk about your Project

Relatetd Post

Recent Posts

- CNC Machining: The Key Advantages for Efficient and Precise Rapid Prototyping

- Prototyping: 3D Printing vs. CNC Machining

- Automotive Plastic Injection Molding: A Cost-Effective Solution

- Injection Molding: The Ultimate Manufacturing & Design Guide

- What is CNC Machining? A Comprehensive Overview of Precision Manufacturing

Comments are closed