What is CNC Machining? A Comprehensive Overview of Precision Manufacturing

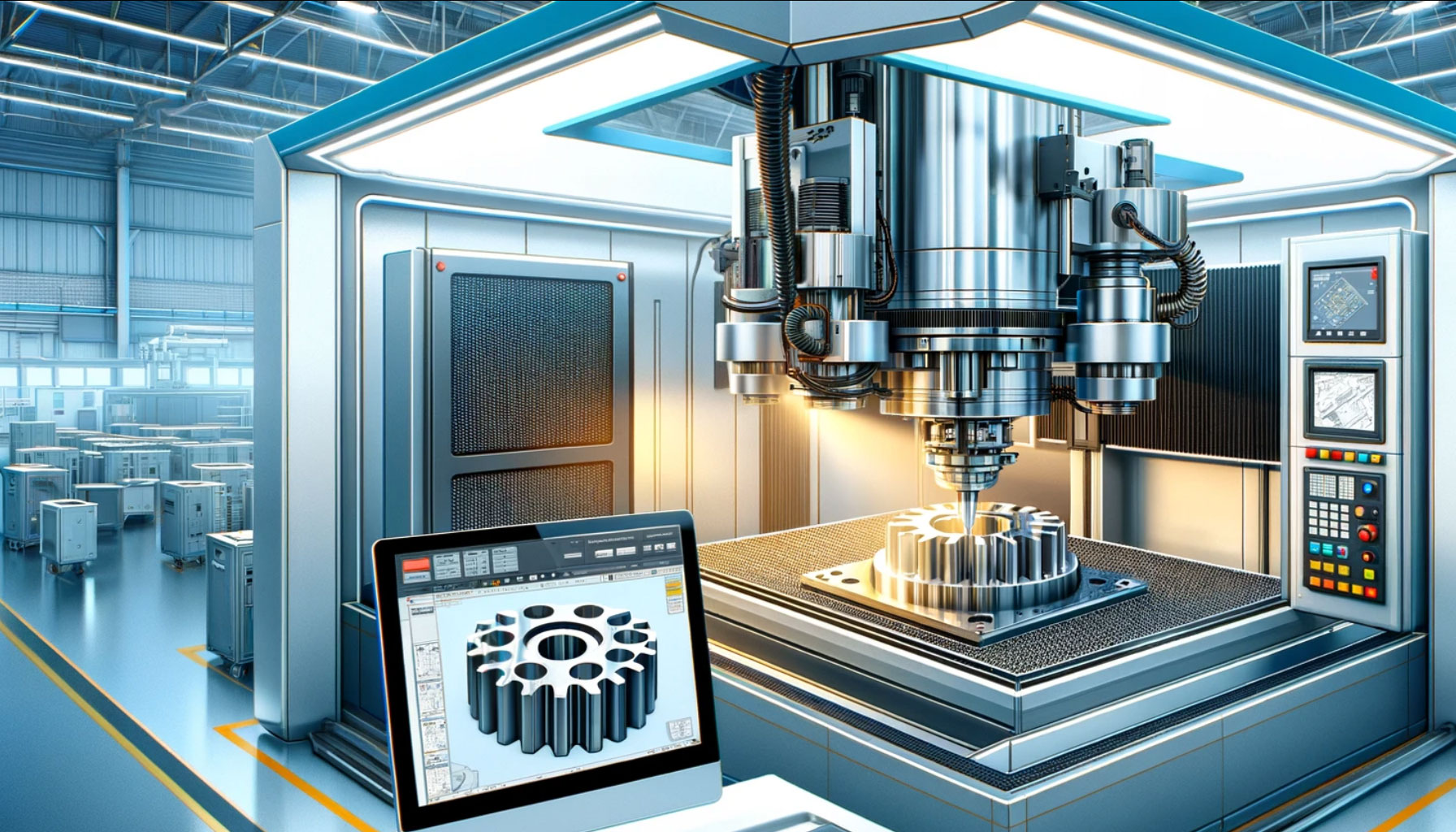

In the industrial landscape, CNC (Computer Numerical Control) machining stands as a cornerstone of precision manufacturing, a beacon of innovation that has redefined efficiency and accuracy. This process, where pre-programmed computer software governs the movement of factory tools and machinery, has become instrumental in executing complex tasks, propelling the manufacturing industry into a new era of technological sophistication.

The Essence of CNC Machining

At its core, CNC machining is the automated process by which a piece of raw material is transformed into a finished product through a subtractive method. Unlike manual machining, where the machinist’s expertise is paramount, CNC machining relies on the precision of pre-programmed software to dictate the motion of the tools. It’s a system that replaces the levers and gears of yesteryear with the bits and bytes of today’s digital era.

CNC Machining: The Process Simplified

The journey from concept to reality in CNC machining starts with a detailed CAD (Computer-Aided Design) model. This digital design is then converted into a language that machines can understand—usually G-code—controlling the cuts, speeds, and movements of the tools with unmatched precision. The result is a product that precisely matches the original design, with little to no variance.

The Precision Engineering Behind CNC Machining

Precision is the hallmark of CNC machining. This method allows for the production of parts with intricate details and tight tolerances that manual machining cannot achieve. It’s a form of engineering that demands rigorous standards, ensuring that every product manufactured meets stringent quality control measures.

CNC Machining Across Industries

CNC machining’s versatility makes it a prized process across various industries. In the aerospace sector, it’s responsible for creating components that can withstand extreme conditions. In the automotive industry, it’s favored for its ability to produce parts en masse while maintaining consistency and quality. The medical field relies on CNC machining to create precise and reliable implants and devices that adhere to critical health and safety regulations.

Advantages of CNC Over Manual Machining

CNC machining trumps manual machining with its ability to automate complex, repetitive tasks, resulting in a higher degree of precision, repeatability, and speed. It minimizes human error, ensuring that each piece produced is virtually identical to the last, a necessity in industries where consistency is critical.

How accurate is CNC machining?

CNC machining is known for its exceptional accuracy and precision. The level of accuracy achieved in CNC machining depends on various factors, including the machine’s capabilities, the quality of the tools used, and the expertise of the operator. Modern CNC machines have advanced features and technologies that allow for incredibly precise machining. These machines are equipped with high-resolution linear encoders, which provide accurate position feedback and allow for precise control over the cutting tools. Additionally, CNC machines are capable of making micro-adjustments to achieve the desired level of accuracy. The accuracy of CNC machining is typically measured in terms of tolerances. Tolerance refers to the allowable deviation from the intended dimensions of a part. CNC machines can achieve tolerances as tight as a few thousandths of an inch (0.025 mm).

However, it is important to note that achieving tight tolerances requires careful planning, tool selection, and machine setup. To ensure accuracy, CNC machines are often calibrated regularly to maintain their performance. Regular maintenance and calibration help to minimize any potential errors and ensure consistent accuracy over time. It is worth mentioning that the accuracy of CNC machining can also be affected by the material being machined. Some materials, such as metals, are more challenging to machine accurately due to their properties, such as thermal expansion. However, experienced CNC operators are skilled in selecting appropriate cutting parameters and techniques to minimize these challenges and achieve the desired level of accuracy. Overall, CNC machining offers high accuracy and precision, making it suitable for a wide range of applications.

The Future of CNC Machining: Where Precision Meets Innovation

The future of CNC machining is intertwined with technological advancements such as the integration of AI, advanced software, and IoT. These innovations promise to heighten the precision, efficiency, and capabilities of CNC machines, making them even more integral to modern manufacturing processes.

Diving Deeper into CNC Machining Centers

CNC machining centers are the workhorses of the CNC world. These sophisticated machines, often referred to as CNC mills, offer unparalleled versatility and operate on multiple axes to create complex geometries with precision. The most advanced among them, the 5-axis CNC machining centers, can manipulate the workpiece on five different axes simultaneously, enabling the creation of intricate and complex parts with incredible accuracy.

Key Benefits of CNC Machining Centers

One of the primary benefits of CNC machining centers is their ability to reduce the need for multiple setups. This not only shortens production time but also enhances accuracy by minimizing the possibility of human error between operations. It’s an attribute that’s particularly beneficial in the context of CNC Machining Services offered by LK Moulds, where time-efficiency translates directly to cost-effectiveness for our clients.

The Role of 5-Axis CNC Machining

5-Axis CNC machining is a leap forward in manufacturing capabilities. By providing the ability to maintain an uninterrupted cutting tool-to-workpiece angle, it allows for more complex designs with smoother surface finishes. This technology is essential for industries that require highly specialized components, such as aerospace and medical device manufacturing.

CNC Machining Services: Meeting Modern Demands

CNC machining services are crucial for companies looking to stay competitive in today’s fast-paced market. LK Moulds’ CNC Machining Services are designed to meet these demands, offering clients a rapid turnaround for prototype development and high-precision production for their end-use parts.

Precision Machining: CNC’s Competitive Edge

When it comes to cnc precision machining, the attention to detail is second to none. This process involves cutting a material to exact measurements and specifications, which is critical for the functionality and interoperability of parts, especially in high-stakes applications like aerospace and defense.

CNC Machining in China: A Global Manufacturing Powerhouse

China has emerged as a leader in CNC machining, offering a broad spectrum of services with a focus on quality and cost-effectiveness. CNC Machining China has become synonymous with reliability, driven by an industry that’s continuously innovating and expanding its capabilities to serve a global clientele.

Conclusion of Part Two

CNC machining centers, and in particular, 5-axis CNC machines, represent the pinnacle of precision manufacturing. They stand as a testament to the technological advancements that have shaped modern production methodologies. Services such as those provided by LK Moulds are at the forefront of this innovation, ensuring that clients have access to the best in CNC machining technology.

CNC Machining and Prototyping: Bringing Ideas to Life

Prototyping is a critical phase in the product development cycle, and CNC machining shines brightly in this arena. Prototype CNC machining allows designers and engineers to test and refine their concepts with speed and precision. By creating accurate prototypes, companies can expedite the process from design to production, ensuring that the end product meets all specifications and requirements.

The Impact of CNC Machining on Product Development

The ability to rapidly produce prototypes is invaluable in today’s fast-paced market. CNC machining facilitates quick iterations, allowing for a seamless transition from prototyping to mass production. This rapid prototyping capability is a cornerstone of the Rapid Prototyping Services provided by LK Moulds, enabling clients to stay agile and responsive to market demands.

CNC Machining Direct: The Direct Route to Manufacturing Excellence

The concept of CNC machining direct refers to the straightforward, no-nonsense approach to manufacturing that CNC technology enables. By reducing the complexity of production processes, CNC machining offers a direct path from digital design to physical part, without the need for intermediary steps that can introduce errors and delays.

CNC Machining’s Role in Customization and Personalization

The trend towards customization and personalization in manufacturing is growing, and CNC machining is at the forefront of this movement. By allowing for small-batch production with the same level of precision as mass production, CNC technology enables manufacturers to cater to specific customer needs without compromising on quality.

CNC Machining: The Engine of Modern Manufacturing

CNC machining isn’t just a tool; it’s the engine that drives modern manufacturing. Its ability to produce complex parts with high precision and repeatability makes it indispensable in today’s industrial landscape. From producing single, bespoke components to fulfilling large orders, CNC machining stands as a versatile and reliable manufacturing method.

Exploring the Breadth of CNC Machining Applications

The applications of CNC machining are as varied as the industries it serves. Whether it’s creating detailed components for the aerospace industry, durable parts for automotive manufacturers, or precise instruments for medical professionals, CNC machining has proven its worth as a flexible and dependable manufacturing solution.

Conclusion of Part Three

CNC machining is more than just a method of manufacturing; it’s a catalyst for innovation, a means of turning the theoretical into the tangible. With its prominent role in prototyping and its ability to adapt to the bespoke needs of various industries, CNC technology has become an integral part of the manufacturing narrative. As a leader in precision manufacturing, LK Moulds embodies the essence of CNC machining, providing services that help clients navigate the complexities of product development with confidence and ease.

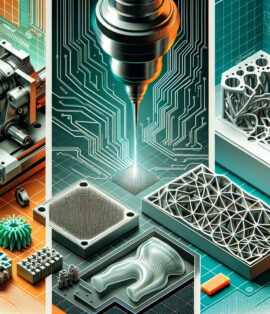

CNC Machining: A Symphony of Precision Tools and Machinery

In the realm of CNC machining, a diverse array of tools and machinery harmonizes to fabricate components with meticulous accuracy. CNC mills, lathes, plasma cutters, and electric discharge machines (EDMs) are just a few of the instruments in this technological orchestra, each playing a vital role in shaping materials into their final forms.

CNC Mills: The Backbone of Machining Operations

CNC mills are the backbone of machining operations, capable of handling a variety of materials and production needs. From simple drilling tasks to complex, multi-axis machining, CNC mills adapt to the demands of precision manufacturing. With advancements in mill technology, operators can now oversee operations that once would have required multiple machines, streamlining the production process and enhancing efficiency.

Lathes: Precision in Circular Motion

CNC lathes bring precision to circular motion, expertly carving symmetrical objects with ease. The adaptability of CNC lathes makes them suitable for a broad spectrum of industries, from intricate jewelry design to the robust needs of the automotive sector. Their ability to produce complex designs quickly and accurately exemplifies the transformative impact of CNC technology on traditional manufacturing practices.

Plasma Cutters and Electric Discharge Machines: Shaping the Future

Plasma cutters and EDMs have reshaped the landscape of manufacturing by offering unique ways to cut and mold materials. Plasma cutters excel in slicing through metal with high-speed, high-temperature ionized gas, while EDMs skillfully sculpt materials through controlled electrical discharges. These tools exemplify the innovative spirit of CNC machining, pushing the boundaries of what’s possible in material design and engineering.

The Versatility of CNC Machinery in Manufacturing

The versatility of CNC machinery lies in its ability to accommodate an array of manufacturing needs. From CNC Machining Centers that offer comprehensive solutions to dedicated machines for specialized tasks, CNC technology provides a level of flexibility and precision that is unparalleled in the manufacturing industry.

Customization: Meeting Client-Specific Demands

CNC technology excels in customization, meeting client-specific demands with precision. At LK Moulds, our CNC Machining Services are tailored to each client’s unique needs, ensuring that every component we produce aligns perfectly with their specifications and quality standards.

Conclusion of Part Four

The symphony of CNC machinery is a testament to the innovation and precision that define modern manufacturing. As we look to the future, the continued evolution of CNC technology promises even greater advancements in the speed, accuracy, and capabilities of manufacturing processes. LK Moulds remains committed to harnessing the full potential of CNC machining to deliver exceptional results for our clients.

Emerging Trends in CNC Machining and Future Outlook

The future of CNC machining is shaped by emerging trends that focus on increased automation, improved precision, and greater integration with digital technologies. Innovations like artificial intelligence (AI) and the Internet of Things (IoT) are set to further revolutionize CNC machining, making machines smarter, more efficient, and more connected.

CNC Machining: Embracing the Digital Revolution

The digital revolution in CNC machining is characterized by smart factories where CNC machines communicate with each other, optimizing production workflows and reducing downtimes. The integration of digital twin technology allows for virtual simulation and testing of CNC programs, ensuring flawless operation before actual production begins.

Sustainability and CNC Machining: A Responsible Approach

Sustainability is becoming increasingly important in manufacturing, and CNC machining is adapting to this trend by optimizing processes to reduce waste and energy consumption. By refining production techniques and using materials more efficiently, CNC machining is contributing to a more sustainable manufacturing environment.

Custom CNC Solutions: Tailored for Excellence

At LK Moulds, we understand that the future is custom. That’s why we offer tailored CNC solutions that meet the specific needs of our clients. Our Custom CNC Machining Services are designed to provide the flexibility and precision required for custom projects, ensuring that each client receives parts that meet their exact requirements.

CNC Machining and the Global Market: Staying Ahead of the Curve

In the global market, staying competitive means staying ahead of technological advancements. LK Moulds’ commitment to innovation in CNC Machining China ensures that we remain at the forefront of the industry, providing our clients with access to the latest CNC technologies and services.

The Future Is Here with LK Moulds’ CNC Machining Services

As we embrace these trends, LK Moulds is positioned to lead the way in precision manufacturing. Our state-of-the-art CNC Machining Services are ready to meet the challenges of the future, delivering high-quality, precision-engineered parts that drive innovation and success for our clients.

Conclusion of the Article

CNC machining is an ever-evolving field that continues to push the boundaries of manufacturing. With its unparalleled precision, adaptability, and integration with cutting-edge digital technologies, CNC machining stands as a pillar of modern production. At LK Moulds, we are dedicated to providing our clients with the very best in CNC machining solutions, ensuring that they receive the highest quality parts and services to meet the demands of a dynamic market. As the industry looks to the future, we remain committed to innovation, excellence, and sustainability in all our CNC machining endeavors.

Our team is here to answer your questions

Let’s talk about your Project

Relatetd Post

Recent Posts

- CNC Machining: The Key Advantages for Efficient and Precise Rapid Prototyping

- Prototyping: 3D Printing vs. CNC Machining

- Automotive Plastic Injection Molding: A Cost-Effective Solution

- Injection Molding: The Ultimate Manufacturing & Design Guide

- What is CNC Machining? A Comprehensive Overview of Precision Manufacturing

Comments are closed