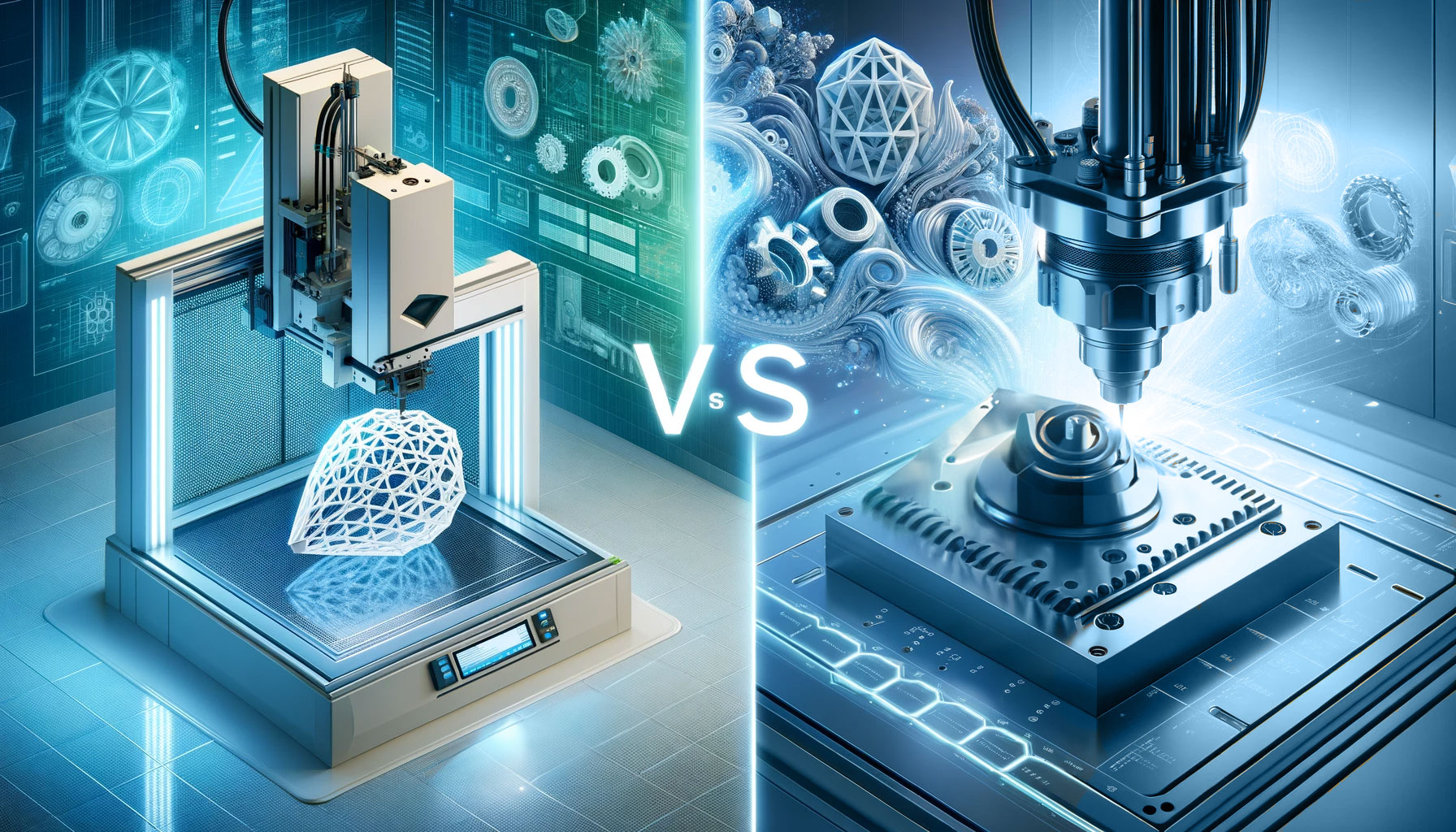

Introduction to Manufacturing Technologies

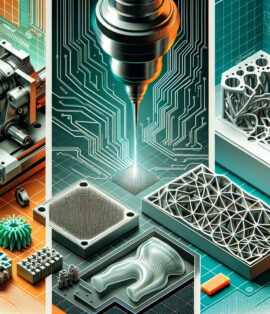

In the realm of manufacturing, two technologies have risen as frontrunners for rapid prototyping and production: 3D printing and CNC machining. Both have transformed how products are designed, prototyped, and manufactured, each offering unique advantages and considerations. This article delves into a comprehensive comparison, equipping decision-makers with the knowledge to choose the optimal technology for their specific needs.

The Emergence of 3D Printing

3D printing, or additive manufacturing, has become synonymous with innovation in manufacturing. It allows for the layer-by-layer construction of objects directly from digital models, offering unparalleled flexibility in design. The technology has made it possible to create complex geometries that were once deemed impossible or too costly to produce with traditional methods.

The Precision of CNC Machining

Conversely, CNC (Computer Numerical Control) machining is a subtractive manufacturing process that removes material from a solid block, known as the workpiece, to form the desired shape. Renowned for its precision, CNC machining is capable of producing highly accurate and consistent parts, making it the go-to choice for applications where tolerance and finish are critical.

Comparative Factors

When it comes to selecting between 3D printing and CNC machining, several factors come into play. Each method brings its own set of strengths and challenges, and understanding these will guide you to the best choice for your project.

Precision and Tolerance

3D Printing: While 3D printing technology has made significant strides in precision, it generally offers slightly lower tolerances compared to CNC machining. The layer-by-layer approach can introduce variability, especially on the z-axis.

CNC Machining: CNC machining excels in precision. The ability to follow complex geometries with high accuracy makes it ideal for parts that require tight tolerances. It remains the industry standard for precision-critical components.

Material Diversity

3D Printing: Offers a broad array of materials, including plastics, resins, and metals. However, the range of materials that can be used in 3D printing is still expanding, and not all materials are suited for every 3D printing technology.

CNC Machining: Almost any material can be machined, from common metals to engineering plastics. This versatility ensures that the material properties of the final part are exactly as required for its intended use.

Speed and Turnaround Time

3D Printing: It is generally faster for producing a single prototype since it requires less setup time. The printing process can be slow, however, especially for high-volume runs.

CNC Machining: While setup times can be longer, the actual machining process is often quicker than 3D printing. For larger production runs, CNC machining is typically the faster method.

Cost Analysis

3D Printing: The cost of 3D printing has reduced over time, making it more accessible. It is cost-effective for small runs and complex designs that would require expensive tooling in other processes.

CNC Machining: The initial setup and tooling costs can be high, but these are offset by the speed and efficiency of the process for larger volumes. Per-unit costs decrease significantly as volume increases.

Design Complexity and Capabilities

3D Printing: Excels with complexity, allowing for intricate designs with internal structures and complex geometries without a significant increase in price.

CNC Machining: While it is possible to machine complex parts, the cost and feasibility can be limiting factors. The subtractive nature of the process also imposes some design restrictions.

Post-Processing Requirements

3D Printing: Often requires additional finishing steps to achieve the desired surface quality. Supports used in the printing process must be removed, and the surface may need to be sanded or otherwise finished.

CNC Machining: Typically produces parts with a higher initial surface finish quality. Additional post-processing can be minimal unless a very high level of finish is required.

Environmental Impact and Sustainability

3D Printing: Tends to produce less waste as it only uses material necessary to build the part. However, the energy consumption per unit can be high, and not all printing materials are recyclable.

CNC Machining: Produces more waste due to the subtractive process, but the materials are often recyclable. Energy consumption is generally lower on a per-part basis for larger production runs.

Conclusion: Choosing the Right Technology for Your Project

Deciding between 3D printing and CNC machining hinges on the specific requirements of your project. For one-off prototypes or parts with complex internal geometries, 3D printing may be the most efficient route. For high precision, tight tolerances, and larger production volumes, CNC machining is often the preferred choice.

In navigating these options, consider not just the cost and time implications, but also the material requirements, design specifications, and end-use application. By weighing these factors, you can select a manufacturing process that aligns with your project’s goals, ensuring a successful outcome.

Discover more about CNC Machining and its benefits for your manufacturing needs on our service page. For insights into the versatile applications of 3D Printing, visit our dedicated section.

Our team is here to answer your questions

Let’s talk about your Project

Relatetd Post

Recent Posts

- CNC Machining: The Key Advantages for Efficient and Precise Rapid Prototyping

- Prototyping: 3D Printing vs. CNC Machining

- Automotive Plastic Injection Molding: A Cost-Effective Solution

- Injection Molding: The Ultimate Manufacturing & Design Guide

- What is CNC Machining? A Comprehensive Overview of Precision Manufacturing

Comments are closed