Mastering Aesthetics and Functionality: The Best Surfaces for CNC Machined Parts

I. Introduction

II. Importance of Surface Finishing in CNC Machining

III. Overview of Surface Finishes

IV. Detailed Comparison Table

V. In-Depth Look at Each Surface Finish

A. Anodizing

B. Bead Blasting

C. Powder Coating

D. Electroplating

E. Brushing

F. Polishing

VI. Pros and Cons of Each Surface Finish

VII. How to Choose the Right Surface Finish for Your Project

VIII. Best Practices for the Optimal Surface Finishes for CNC Machining

IX. Conclusion

Surface Finishes for CNC Machining

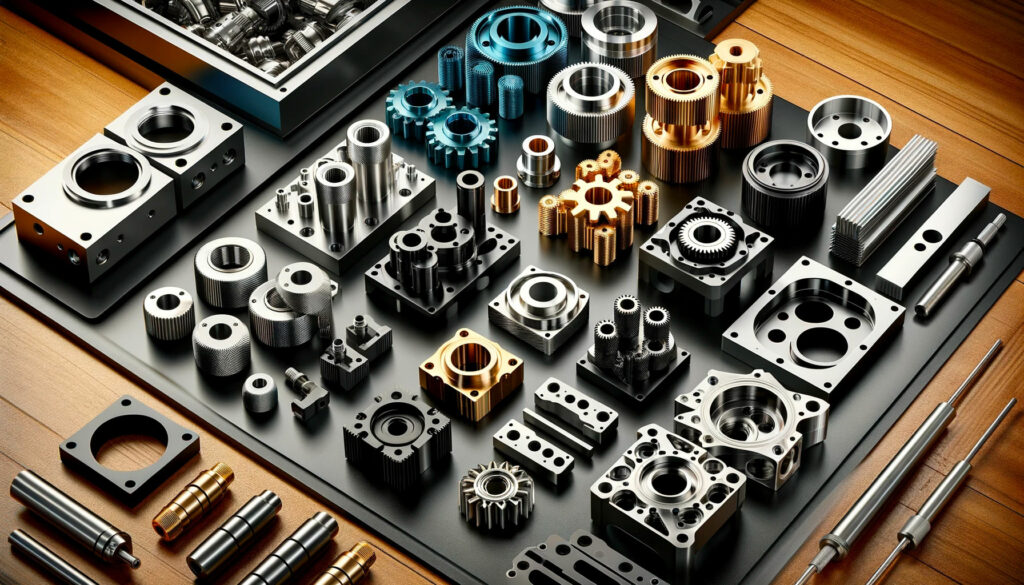

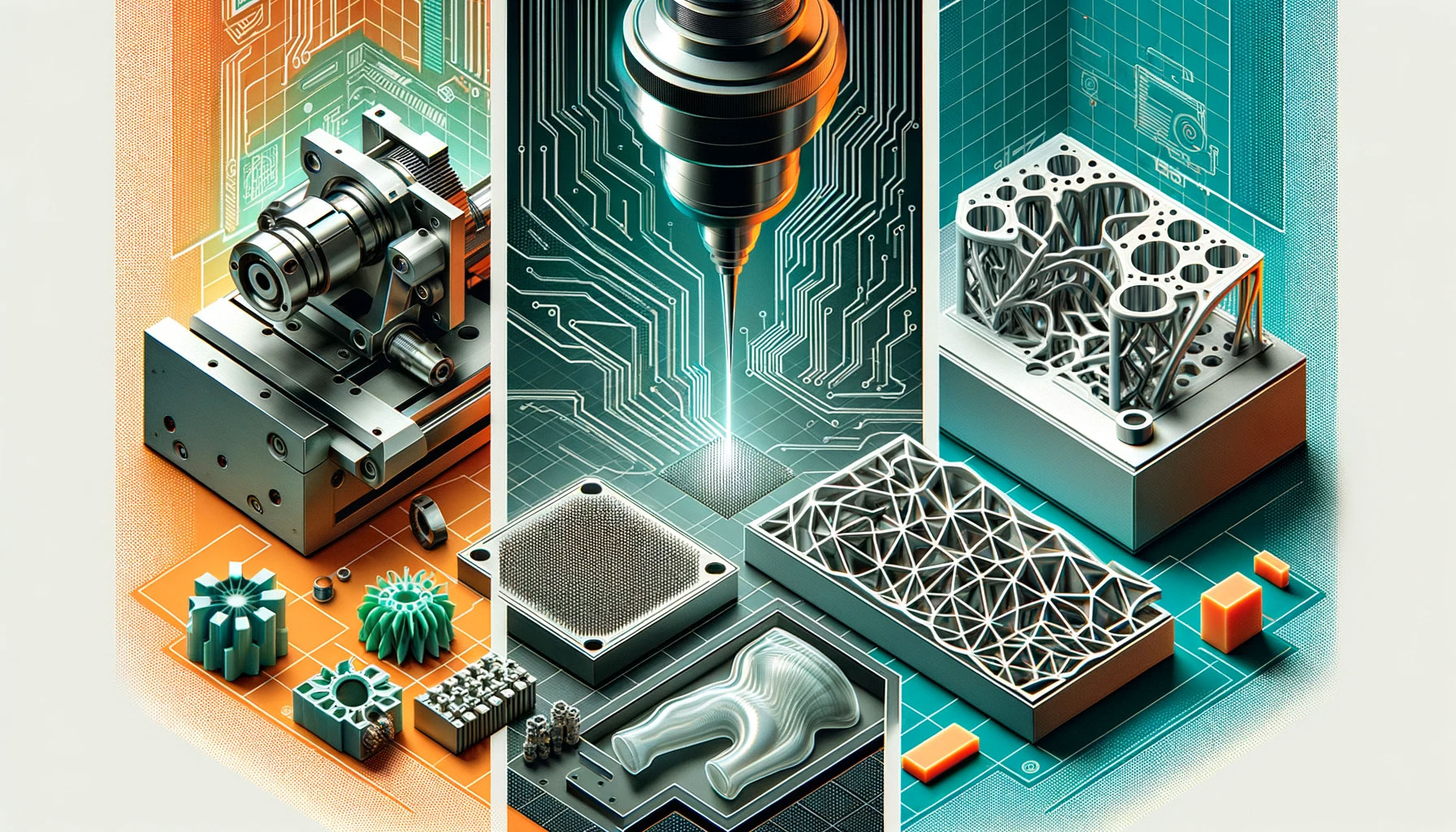

Precision CNC machining has revolutionized the manufacturing industry, offering the ability to create complex parts with unparalleled accuracy. However, it’s the surface finish that often takes these parts from merely functional to aesthetically pleasing and durable. In this guide, we will explore the best surface finishes for CNC machined parts, comparing their finish quality, tolerances, level of protection, cost, and material suitability.

Importance of Surface Finishing in CNC Machining

Surface finishing on CNC machined parts is not just about appearance. It also enhances performance, increases resistance to corrosion and wear, and can even impact the mechanical properties of the parts. From anodizing to powder coating, each method offers unique benefits and potential drawbacks.

In-Depth Comparison Table of Each CNC Machining Surface Finish

| Finish Type | Finish Quality | Tolerances | Protection Level | Cost | Material Suitability |

|---|---|---|---|---|---|

| Anodizing | Smooth, matte/glossy | Tight | Excellent corrosion | Moderate | Aluminum, Titanium |

| Bead Blasting | Uniform, matte | Moderate | None (cosmetic only) | Low | Most metals, some plastics |

| Powder Coating | Thick, even | Moderate to loose | High corrosion and wear resistance | Moderate | Metals, some plastics |

| Electroplating | Smooth, metallic | Varies | Good corrosion, wear, and conductivity | High | Most metals |

| Brushing | Satin, unidirectional | Moderate | None (cosmetic only) | Low to moderate | Most metals |

| Polishing | High gloss, mirror | Moderate to loose | Slight corrosion resistance | High | Most metals, some plastics |

This table serves as a quick reference to compare the different surface finishes that can be applied to CNC machined parts. It is important to note that the actual suitability and effectiveness of each finish can depend on the specific application and material used, as well as the desired outcome of the part. Each finish has its own set of advantages and drawbacks, and the selection should be made based on the requirements of the end-use of the parts.

How to Choose the Right Surface Finish for Your CNC Machining Project

Choosing the right surface finish involves considering the part’s application, the environment it will be used in, and the desired aesthetics. We will guide you through the decision-making process, helping you match your needs with the right finishing technique.

Best Practices for the Optimal Surface Finishes for CNC Machining

Selecting the ideal surface finish for CNC machined components is a pivotal decision that impacts both the functionality and the aesthetic appeal of your parts. At LK Moulds, we recognize that each finish from our services portfolio presents unique strengths and limitations tailored to diverse application needs.

To guide your selection, it’s imperative to thoroughly assess the operational demands and visual requirements of your part. Consideration of the part’s interaction with other components, especially under conditions of friction, is crucial in this process.

Moreover, it’s advisable to revisit your part’s environmental exposure during the design and engineering stage. Environmental variables often necessitate more resilient surface finishes than initially anticipated to ensure longevity and performance.

Our Tips for CNC Machined Surface Finishing Excellence

Bead Blasting: Ideal for achieving a consistently smooth, matte appearance without altering dimensional tolerances, bead blasting ensures a refined finish for parts not subjected to high wear.

Anodizing Type II: Enhance your aluminum and titanium parts with a protective yet decorative coating. This finish provides a natural matte hue, marrying durability with visual allure.

Anodizing Type III: For parts in demanding engineering applications, Type III anodizing offers exceptional wear resistance and increased surface hardness, ensuring your components withstand rigorous use.

Powder Coating: When high-impact resilience is paramount, and anodizing isn’t viable, powder coating is the go-to surface finish. It not only elevates impact strength but also offers a wide spectrum of color options to match your design specifications.

Incorporating these insights into your selection strategy ensures your CNC machined parts from LK Moulds meet and exceed the expectations of your application’s performance and aesthetic needs.

Conclusion:

Selecting the right surface finish for CNC machined parts is crucial for optimizing both functionality and aesthetics. Whether you prioritize durability, cost-efficiency, or appearance, understanding the pros and cons of each finish will ensure you make the best choice for your application. By considering the specific demands of your project and the unique qualities of each finishing process, you can enhance the value and performance of your machined components.

The detailed comparison table and in-depth discussion provided in this guide serve as a comprehensive resource for navigating the complex landscape of CNC surface finishes. As advancements in technology continue to expand the possibilities, staying informed will help you leverage the full potential of CNC machining for your manufacturing needs.

Our team is here to answer your questions

Let’s talk about your Project

Recent Posts

- CNC Machining: The Key Advantages for Efficient and Precise Rapid Prototyping

- Prototyping: 3D Printing vs. CNC Machining

- Automotive Plastic Injection Molding: A Cost-Effective Solution

- Injection Molding: The Ultimate Manufacturing & Design Guide

- What is CNC Machining? A Comprehensive Overview of Precision Manufacturing

Comments are closed